Prestige Clothing Caledon is but one of TFG’s clothing factories, part of the largest apparel manufacturing group in South Africa. We have ambitious plans for further growth and job creation.

In the 2022 financial year we produced 15,7 million quick-response units in South Africa and are aiming to increase this to 30 million units by 2026.

We currently have 5 200 manufacturing employees in both TFG’s Prestige Clothing and our strategic CMTs – and our intention is to grow this to 11 200 by 2026.

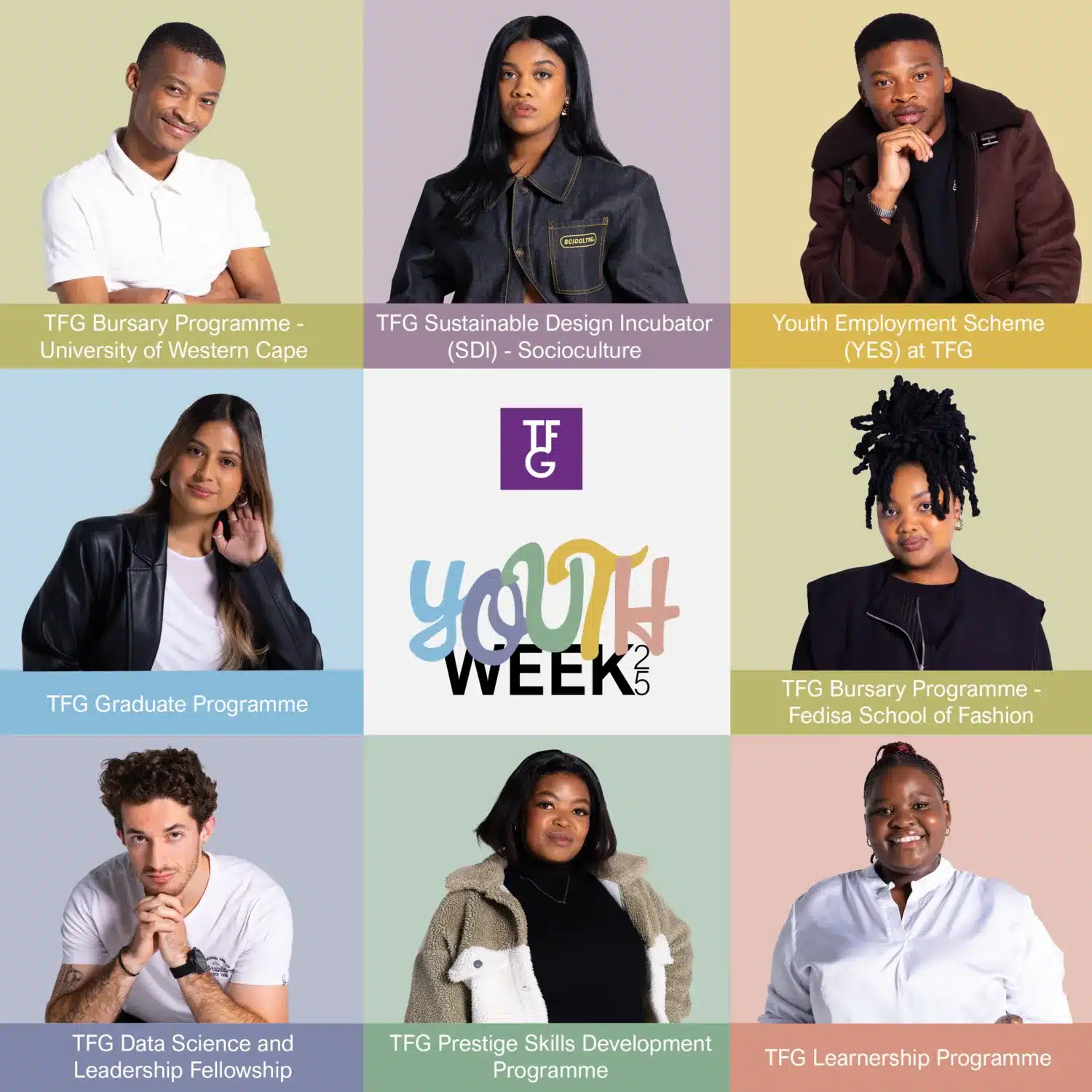

This requires a highly effective recruitment, training and development plan.

Small enterprises are also part of our growth plans for local manufacturing. With the support of government, we are able to help develop suppliers and assist them with compliance and capacity planning.

By investing in local manufacturing – creating jobs and developing small businesses – we play our part in helping South Africans live better lives.

Find out more about a career at TFG – CLICK HERE.

Find out more about being a TFG supplier – CLICK HERE.