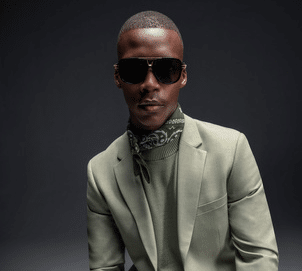

What About The Boys? aims to tackle gender-based violence by working with thousands of high school boys across the country. The programme is designed to guide boys to break free from the rigid and often damaging stereotypes of traditional masculinity that contribute to GBV.

This year Markham and What About The Boys? aim to raise R1.35 million to combat gender-based violence. By purchasing a branded tee or sweater, customers can show their support and solidarity while advocating for change. Markham donates R50 per sale of the tee and R100 per sale of the sweater towards driving this great initiative.

Let’s make a difference and create a better world… together.

For more information about What About The Boys? visit https://www.primestarsdigital.co.za/what-about-the-boys/